Valve Wrench

Ex207 Series

- Non-Sparking

- Non-Magnetic

- Corrosion Resistant

- ISO 9001:2015 certified production, TUV materials certified

- Lifetime Warranty

Applications:

- Non-sparking valve wrench for use in petrochemical, grain production (explosive-dust), utilities, and hazmat applications.

- Non-magnetic valve wrench for use in MRI/NMR, nuclear products, electronic manufacturing, and other sensitive equipment.

- Corrosion Resistant valve wrench for use in desalination plants, chemical/paper manufacturing, and shipyards.

- Standard Sizes

- ALLOYS & USE

| A = Aluminum Bronze | B = Copper Beryllium | |

|---|---|---|

| Example: | Ex207-30A | Ex207-30B |

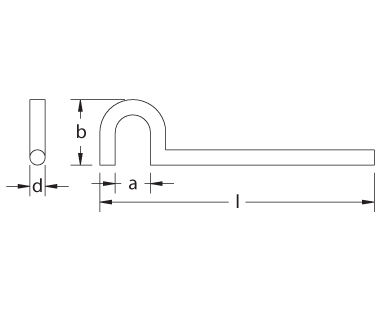

| No. | a inch | b inch | d inch | l inch | Wt. lbs. | a mm | b mm | d mm | l mm | Wt. kg |

|---|---|---|---|---|---|---|---|---|---|---|

| Ex207-30 | 1 3/16 | 2 1/4 | 1/2 | 8 | 0.66 | 30 | 56 | 13 | 200 | 0.30 |

| Ex207-32 | 1 1/4 | 2 3/8 | 9/16 | 10 | 0.93 | 32 | 60 | 14 | 250 | 0.42 |

| Ex207-36 | 1 7/16 | 2 5/8 | 9/16 | 10 3/4 | 1.15 | 36 | 66 | 15 | 270 | 0.52 |

| Ex207-41 | 1 5/8 | 2 7/8 | 5/8 | 12 | 1.46 | 41 | 73 | 16 | 300 | 0.66 |

| Ex207-50 | 2 | 3 7/16 | 11/16 | 12 3/4 | 2.02 | 50 | 86 | 18 | 320 | 0.92 |

| Aluminum-Bronze (AlBr) Alloy | Copper-Beryllium (CuBe2) Alloy | |

|---|---|---|

| Zone Compatibility | Fulfill demand in ATEX Directive 1999/92/EC for work in Zones 0, 1, 2, 20, 21 and 22, M1 & M2 | Fulfill demand in ATEX Directive 1999/92/EC for work in Zones 0, 1, 2, 20, 21 and 22, M1 & M2 |

| Hardness | 27 HRC | 38 HRC |

| Durability | Not as durable as CuBe. | Very durable due to high hardness and tensile strength. |

| Magnetic Properties | Low magnetism due to minimal ferrous components. Appropriate for non-critical non-magnetic applications. | Non-ferrous components; safer for applications demanding non-magnetic properties. |

| Composition | Al: 10.3% Fe: 4.5% Ni: 4.5% Other: 0.5% Cu: Balance | Be: 1.9% Co + Ni: 0.4% Other: 0.5% Cu: Balance |

| Proper Use | Misuse |

| 1. Oil pliers occasionally. A drop of oil at the hinge will lengthen tool life and assure easy operation. 2. Safety glasses should be worn when cutting wire, etc. to protect eyes from being struck by the end of the object being cut. 3.WARNING: Ordinary plastic dipped handles are designed for comfort, not electrical insulation. Tools having high dielectric insulation are available and are so identified. Do not confuse the two. | 1. Pliers should not be used for cutting hardened wire unless specifically manufactured for this service. 2. Never expose pliers to excessive heat. This may draw the temper and ruin the tool. 3. Always cut at right angles. Never rock from side to side or bend the wire back and forth against the cutting blades. 4. Don't bend stiff wire with light pliers. Needle nose pliers can be damaged by using the tips to bend too large a wire. Use a sturdier tool. 5. Never use pliers as a hammer nor hammer on the handles. They may crack or break, or blades may be nicked by such abuse. 6. Never extend the length of handles to secure greater leverage. Use a larger pair of pliers or a bolt cutter. 7. Pliers should not be used on nuts or bolts. A wrench will do the job better and with less risk of damage to the fastener. |

| Downloads: |

|---|

Urgent Weekend/Holiday Fulfillment Available - Click For Details

Urgent Weekend/Holiday Fulfillment Available - Click For Details