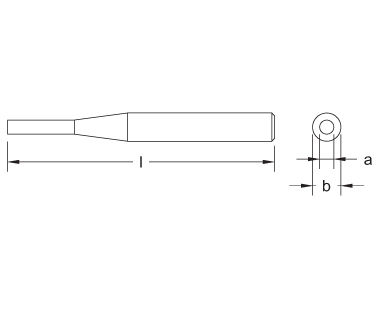

Pin Punch

Ex301P Series

- Non-Sparking

- Non-Magnetic

- Corrosion Resistant

- ISO 9001:2015 certified production, TUV materials certified

- Lifetime Warranty

Applications:

- Non-sparking pin punch for use in petrochemical, grain production (explosive-dust), utilities, and hazmat applications.

- Non-magnetic pin punch for use in MRI/NMR, nuclear products, electronic manufacturing, and other sensitive equipment.

- Corrosion Resistant pin punch for use in desalination plants, chemical/paper manufacturing, and shipyards.

- Standard Sizes

- Metric Sizes

- Alloys & Use

| No. | a inch | b inch | l inch | Wt. lbs. |

|---|---|---|---|---|

| Ex301P-005UB | 7/128 | 3/8 | 4 3/8 | 0.10 |

| Ex301P-010UB | 9/128 | 3/8 | 4 3/8 | 0.10 |

| Ex301P-015UB | 1/16 | 3/8 | 6 | 0.16 |

| Ex301P-020UB | 3/32 | 3/8 | 4 3/8 | 0.10 |

| Ex301P-025UB | 7/64 | 3/8 | 4 3/8 | 0.11 |

| Ex301P-030UB | 1/8 | 3/8 | 6 | 0.15 |

| Ex301P-035UB | 3/16 | 3/8 | 6 | 0.15 |

| Ex301P-040UB | 1/4 | 3/8 | 6 | 0.16 |

| Ex301P-045UB | 5/16 | 7/16 | 6 | 0.25 |

| Ex301P-050UB | 3/8 | 9/16 | 6 | 0.35 |

| No. | a mm | b mm | l mm | Wt. kg |

|---|---|---|---|---|

| Ex301P-1.4B | 1.4 | 10 | 110 | 0.05 |

| Ex301P-1.8B | 1.8 | 10 | 110 | 0.05 |

| Ex301P-2B | 2 | 10 | 150 | 0.07 |

| Ex301P-2.4B | 2.4 | 10 | 110 | 0.05 |

| Ex301P-2.8B | 2.8 | 10 | 110 | 0.05 |

| Ex301P-3B | 3 | 10 | 150 | 0.07 |

| Ex301P-4B | 4 | 10 | 150 | 0.07 |

| Ex301P-5B | 5 | 10 | 150 | 0.07 |

| Ex301P-6B | 6 | 10 | 150 | 0.07 |

| Ex301P-7B | 7 | 12 | 150 | 0.11 |

| Ex301P-8B | 8 | 12 | 150 | 0.11 |

| Ex301P-10B | 10 | 14 | 150 | 0.16 |

| Aluminum-Bronze (AlBr) Alloy | Copper-Beryllium (CuBe2) Alloy | |

|---|---|---|

| Zone Compatibility | Fulfill demand in ATEX Directive 1999/92/EC for work in Zones 0, 1, 2, 20, 21 and 22, M1 & M2 | Fulfill demand in ATEX Directive 1999/92/EC for work in Zones 0, 1, 2, 20, 21 and 22, M1 & M2 |

| Hardness | 27 HRC | 38 HRC |

| Durability | Not as durable as CuBe. | Very durable due to high hardness and tensile strength. |

| Magnetic Properties | Low magnetism due to minimal ferrous components. Appropriate for non-critical non-magnetic applications. | Non-ferrous components; safer for applications demanding non-magnetic properties. |

| Composition | Al: 10.3% Fe: 4.5% Ni: 4.5% Other: 0.5% Cu: Balance | Be: 1.9% Co + Ni: 0.4% Other: 0.5% Cu: Balance |

| Proper Use | Misuse |

| Drift pins are designed for aligning holes in metal. | Never use a drift pin as a punch. Never strike a drift pin if either end is chipped or mushroomed. |

| Downloads: |

|---|

Urgent Weekend/Holiday Fulfillment Available - Click For Details

Urgent Weekend/Holiday Fulfillment Available - Click For Details