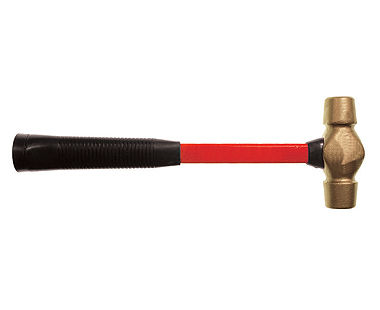

Double-Face Machinists' Hammer

Ex103U Series

- Non-Sparking

- Non-Magnetic

- Corrosion Resistant

- ISO 9001:2015 certified production, TUV materials certified

- Lifetime Warranty

Hammer handle appearance may vary from photos shown.

Applications:

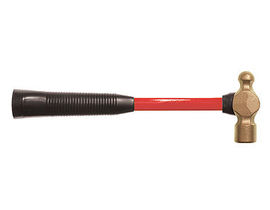

- Non-sparking double-face machinists' hammers for use in petrochemical, grain production (explosive-dust), utilities, and hazmat applications.

- Non-magnetic double-face machinists' hammers for use in MRI/NMR, nuclear products, electronic manufacturing, and other sensitive equipment.

- Corrosion Resistant double-face machinists' hammers for use in desalination plants, chemical/paper manufacturing, and shipyards.

- Standard Sizes

- Alloys & Use

| A = Aluminum Bronze | B = Copper Beryllium | |

|---|---|---|

| Example: | Ex103U-0025A | Ex103U-0025B |

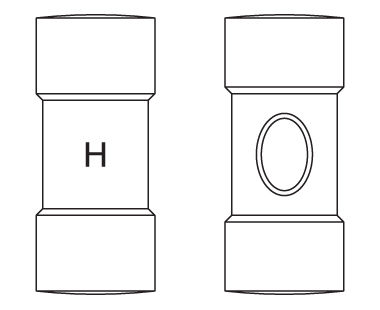

| No. | H lbs. | H kg | Handle Length |

|---|---|---|---|

| Ex103U-0025 | 0.25 | 0.12 | 10"/250mm |

| Ex103U-0150 | 1.50 | 0.68 | 14.25"/360mm |

| Ex103U-0175 | 1.75 | 0.80 | 14.25"/360mm |

| Ex103U-0200 | 2.00 | 0.91 | 14.25"/360mm |

| Aluminum-Bronze (AlBr) Alloy | Copper-Beryllium (CuBe2) Alloy | |

|---|---|---|

| Zone Compatibility | Fulfill demand in ATEX Directive 1999/92/EC for work in Zones 0, 1, 2, 20, 21 and 22, M1 & M2 | Fulfill demand in ATEX Directive 1999/92/EC for work in Zones 0, 1, 2, 20, 21 and 22, M1 & M2 |

| Hardness | 27 HRC | 38 HRC |

| Durability | Not as durable as CuBe. | Very durable due to high hardness and tensile strength. |

| Magnetic Properties | Low magnetism due to minimal ferrous components. Appropriate for non-critical non-magnetic applications. | Non-ferrous components; safer for applications demanding non-magnetic properties. |

| Composition | Al: 10.3% Fe: 4.5% Ni: 4.5% Other: 0.5% Cu: Balance | Be: 1.9% Co + Ni: 0.4% Other: 0.5% Cu: Balance |

For More Information on Choosing The Correct Alloy for Your Application - Click Here

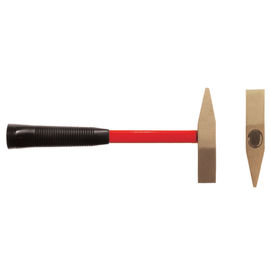

| Proper Use | Misuse |

| Double face machinist's hammers are designed for general sledging operations in striking wood, metal, concrete or stone. Common uses are drifting heavy timbers and striking spikes,cold chisels, rock drills and hardened nails. | Never use a double face machinist's hammer to strike a hammer, sledge, or maul. Never use a double face machinist's hammer with a loose or damaged handle. |

| Downloads: |

|---|

Urgent Weekend/Holiday Fulfillment Available - Click For Details

Urgent Weekend/Holiday Fulfillment Available - Click For Details