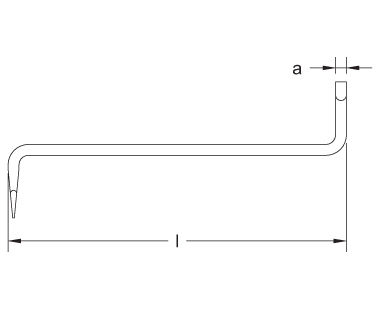

Offset Screwdriver

Ex802 Series

- Non-Sparking

- Non-Magnetic

- Corrosion Resistant

- ISO 9001:2015 certified production, TUV materials certified

- Lifetime Warranty

Applications:

- Non-sparking offset screwdriver for use in petrochemical, grain production (explosive-dust), utilities, and hazmat applications.

- Non-magnetic offset screwdriver for use in MRI/NMR, nuclear products, electronic manufacturing, and other sensitive equipment.

- Corrosion Resistant offset screwdriver for use in desalination plants, chemical/paper manufacturing, and shipyards.

- Standard Sizes

- Metric Sizes

- Alloys & Use

| No. | a inch | b inch | Wt. lbs. |

|---|---|---|---|

| Ex802-010UB | 1/8 | 4 | 0.02 |

| Ex802-020UB | 1/4 | 5-9/16 | 0.11 |

| Ex802-030UB | 3/8 | 7-3/16 | 0.42 |

| Ex802-040UB | 9/16 | 10 | 1.10 |

| No. | a mm | b mm | Wt. kg |

|---|---|---|---|

| Ex802-3 | 3 | 100 | 0.0078 |

| Ex802-4 | 4 | 110 | 0.016 |

| Ex802-6 | 6 | 140 | 0.048 |

| Ex802-8 | 8 | 160 | 0.098 |

| Ex802-10 | 10 | 180 | 0.19 |

| Ex802-12 | 12 | 200 | 0.30 |

| Ex802-14 | 14 | 250 | 0.50 |

| Aluminum-Bronze (AlBr) Alloy | Copper-Beryllium (CuBe2) Alloy | |

|---|---|---|

| Zone Compatibility | Fulfill demand in ATEX Directive 1999/92/EC for work in Zones 0, 1, 2, 20, 21 and 22, M1 & M2 | Fulfill demand in ATEX Directive 1999/92/EC for work in Zones 0, 1, 2, 20, 21 and 22, M1 & M2 |

| Hardness | 27 HRC | 38 HRC |

| Durability | Not as durable as CuBe. | Very durable due to high hardness and tensile strength. |

| Magnetic Properties | Low magnetism due to minimal ferrous components. Appropriate for non-critical non-magnetic applications. | Non-ferrous components; safer for applications demanding non-magnetic properties. |

| Composition | Al: 10.3% Fe: 4.5% Ni: 4.5% Other: 0.5% Cu: Balance | Be: 1.9% Co + Ni: 0.4% Other: 0.5% Cu: Balance |

For More Information on Choosing The Correct Alloy for Your Application - Click Here

| Proper Use | Misuse |

| Keep the screwdriver handle clean; a greasy handle is apt to cause an accident. Use a screw-holding screwdriver to get screws started in awkward, hard-to-reach areas. Screwdrivers used in the shop are best stored in a rack. This way, the proper selection of the right screwdriver can be quickly made. Use a ratchet-type screwdriver for speed and comfort when a great number of screws are to be driven. A rounded tip should be redressed with a file; make sure the edges are straight. Use an offset screwdriver in close quarters where a conventional screwdriver cannot be used. | Don't use a screwdriver with rounded edges or tips; it will slip and cause damage to the work or yourself. Don't use pliers on the handle of a screwdriver to get extra turning power. A wrench should only be used on the square shank or bolster of a screwdriver that is especially designed for that purpose. Don't hold the work in one hand while using the screwdriver with the other. If the screwdriver slips out of the slot (we told you to use the right size screwdriver!) you will be most likely to receive a gash on your hand. Don't use a screwdriver for prying, punching, chiseling, scoring, or scraping. Don't use a screwdriver to check a storage battery or to determine if an electrical circuit is live. Don't expose a screwdriver blade to excessive heat as it may reduce the hardness of the blade. Don't use a screwdriver near a live wire or for electrical testing. Don't use a screwdriver with a split or broken handle. Don't use a screwdriver for stirring paint. |

| Downloads: |

|---|

Urgent Weekend/Holiday Fulfillment Available - Click For Details

Urgent Weekend/Holiday Fulfillment Available - Click For Details