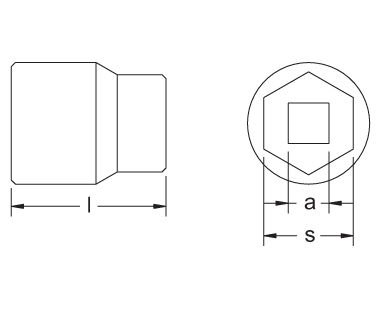

15-Piece Kit - Regular Sockets, 6-Point, 3/8" Drive

Ex1525-Kit

- Non-Sparking

- Non-Magnetic

- Corrosion Resistant

- ISO 9001:2015 certified production, TUV materials certified

- Lifetime Warranty

Applications:

- Non-sparking regular socket kit for use in petrochemical, grain production (explosive-dust), utilities, and hazmat applications.

- Non-magnetic regular socket kit for use in MRI/NMR, nuclear products, electronic manufacturing, and other sensitive equipment.

- Corrosion Resistant regular socket kit for use in desalination plants, chemical/paper manufacturing, and shipyards.

- Standard Sizes

- ALLOYS & USE

| A = Aluminum Bronze | B = Copper Beryllium | |

|---|---|---|

| Example: | Ex1525-KitA | Ex1525-KitB |

| Kit Includes: | |||

|---|---|---|---|

| No. | Dimensions | Quantity | Description |

| Ex1503A-005U | 1/4" | 1 | Socket, 3/8" drive |

| Ex1503A-010U | 5/16" | 1 | Socket, 3/8" drive |

| Ex1503A-015U | 3/8" | 1 | Socket, 3/8" drive |

| Ex1503A-020U | 7/16" | 1 | Socket, 3/8" drive |

| Ex1503A-025U | 1/2" | 1 | Socket, 3/8" drive |

| Ex1503A-030U | 9/16" | 1 | Socket, 3/8" drive |

| Ex1503A-035U | 5/8" | 1 | Socket, 3/8" drive |

| Ex1503A-040U | 11/16" | 1 | Socket, 3/8" drive |

| Ex1503A-045U | 3/4" | 1 | Socket, 3/8" drive |

| Ex1503A-050U | 13/16" | Socket, 3/8" drive | |

| Ex1503A-055U | 7/8" | 1 | Socket, 3/8" drive |

| Ex1501S-A | 3/8" drive | 1 | Ratchet |

| Ex1502-A | 3/8" drive | 1 | Sliding Bar |

| Ex1504A-75U | 3/8" drive | 1 | Extension Bar |

| Ex1506A | 3/8" drive | 1 | Hinged Handle |

| Aluminum-Bronze (AlBr) Alloy | Copper-Beryllium (CuBe2) Alloy | |

|---|---|---|

| Zone Compatibility | Fulfill demand in ATEX Directive 1999/92/EC for work in Zones 0, 1, 2, 20, 21 and 22, M1 & M2 | Fulfill demand in ATEX Directive 1999/92/EC for work in Zones 0, 1, 2, 20, 21 and 22, M1 & M2 |

| Hardness | 27 HRC | 38 HRC |

| Durability | Not as durable as CuBe. | Very durable due to high hardness and tensile strength. |

| Magnetic Properties | Low magnetism due to minimal ferrous components. Appropriate for non-critical non-magnetic applications. | Non-ferrous components; safer for applications demanding non-magnetic properties. |

| Composition | Al: 10.3% Fe: 4.5% Ni: 4.5% Other: 0.5% Cu: Balance | Be: 1.9% Co + Ni: 0.4% Other: 0.5% Cu: Balance |

For More Information on Choosing The Correct Alloy for Your Application - Click Here

| Proper Use | Misuse |

| Hand Socket wrenches are made in a wide range of sizes and capacities. All have square drives ranging from 1/4" to 1". Drive size is a measure of capacity. Since Detachable Socket wrenches provide an almost endless combination of handles, attachments and sockets, it is possible to assemble a proper tool for almost any type of service within the tool's capacity. | Never use a pipe extension or other form of "cheater" to increase the leverage of any wrench. Select a wrench whose opening exactly fits the nut. If possible, always pull on a wrench handle and adjust your stance to prevent a fall if something lets go. There are three types of Sockets: hand, power and impact all different in design and hardness. Hand Sockets should never be used on power drive or impact wrenches. |

| Downloads: |

|---|

Urgent Weekend/Holiday Fulfillment Available - Click For Details

Urgent Weekend/Holiday Fulfillment Available - Click For Details